AI just found the best ingredients for green concrete

After sorting through 1 million material samples, an AI tool has found 19 ideal materials to reduce concrete’s emissions and lower its environmental impact.

June 5, 2025

We use around 30 billion tonnes of concrete every year. That gigantic number bears an equally gigantic carbon footprint. Producing cement, the glue that holds concrete together, is responsible for more than 6% of global greenhouse gas emissions.

So a team of engineers at MIT put artificial intelligence to the task of finding cement alternatives in order to reduce the cost and emissions of concrete. They built an AI system, reported in the journal Communications Materials, to scour through hundreds of thousands of pages of scientific literature.

After sorting through 1 million material samples, the AI tool has found 19 ideal materials to replace cement. Most of these materials are wastes, and putting them to use in concrete mixes instead of landfilling them adds an environmental advantage.

“Some of the most interesting materials that could replace a portion of cement are ceramics,” said Soroush Mahjoubi, a postdoctoral researcher in civil and environmental engineering in a press release. “Old tiles, bricks, pottery—all these materials may have high reactivity.”

It is challenging to reduce cement-associated carbon emissions. That’s because emissions come inherently from the chemical reactions involved and from the fuel burned to heat the raw materials. The best bet to reduce concrete’s emissions, then, is to substitute part of the cement with materials that have a lower environmental impact.

AI is making an adventurous and sustainable plant diet possible

Waste and recycled materials are a prime example. The cement industry has for years used materials like fly ash, a byproduct of coal production, and slag, a byproduct of steelmaking, to replace some of the cement in concrete. But these substitutes face supply constraints because of increasing demand, the MIT team writes.

So the team built a machine learning tool that extracted the chemical compositions of over 14,000 previously used cement and concrete materials from 88,000 academic papers. The model evaluated these candidate materials based on their physical and chemical properties to see if they would replace cement’s trademark properties that are necessary for making concrete, such as its ability to harden when mixed with water.

The model then sorted the materials into 19 types. The substitutes included landfilled fly ashes and metallurgical slags; the ashes of various biomass materials such as rice husk, sugarcane bagasse, wood, and tree bark; construction and demolition wastes such as ceramics, bricks, and concrete; waste glass; municipal solid waste incineration ashes; and mine tailings. The study also identified 25 types of natural rocks that would work.

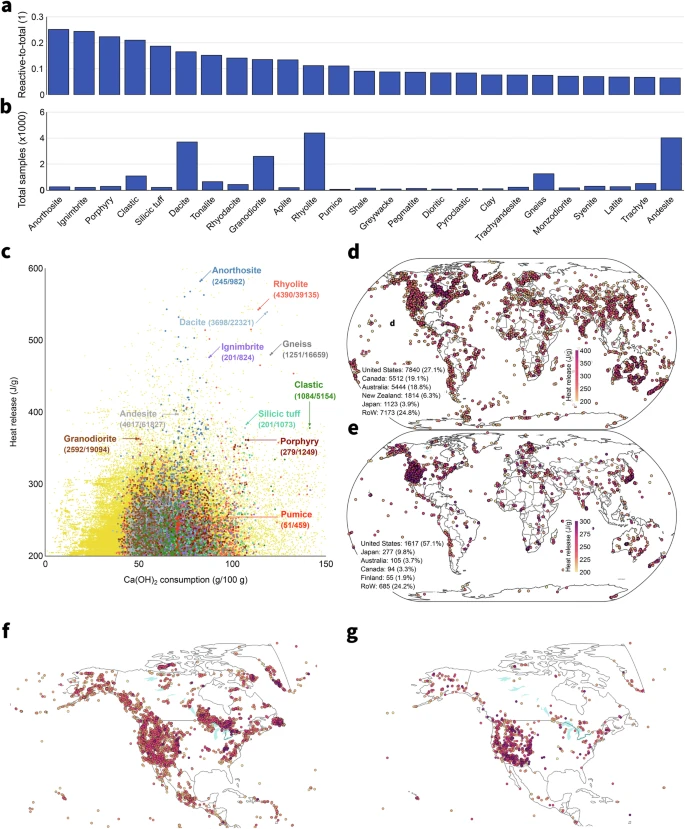

Fig. 4: Discovery of natural cementitious precursors. a Reactive-to-total sample ratio for the 38 rock types exceeding a 5% threshold. b number of moderate-to-high reactivity samples for each rock type. c reactivity variations of selected rock types, chosen based on highest abundance or reactive-to-total ratio, colored by rock types. Below each label, the numbers represent the ratio of moderate-to-high reactive materials to the total number of rock samples of that type, indicated as reactive samples/total samples. Each arrow points to the sample with the highest degree of reactivity. Yellow markers denote rock samples whose rock types were not selected. Geospatial distribution of identified reactive rocks within the globe with pozzolanic (d) and hydraulic (e) behavior. The number preceding each country indicates the number of unique locations with cementitious precursors, and the number in parentheses represents the percentage relative to the total identified locations. Geospatial distribution of discovered reactive rocks within the Northern America with pozzolanic (f) and hydraulic (g) behavior.

Most of the materials are abundant around the globe, and the use of these. And the researchers found that many could be added to concrete mixes simply by grinding, without any additional specialized processing.

Source: Soroush Mahjoubi et al. Data-driven material screening of secondary and natural cementitious precursors. Communications Materials, 2025.

Image: ©Anthropocene Magazine/ AI-generated.