Clearly cool: A transparent paper-based material could replace single-use plastics

The millimeter-thick paperboard behaves just like plastic; it’s strong, transparent, shapeable—and can hold boiling water. But it degrades within a year on the ocean floor.

April 16, 2025

Close to 2 million metric tons of plastic enters the oceans every year from beaches and waterways, according to The Ocean Cleanup Project. Much of that plastic is single-use beverage bottles, cups, and straws.

Researchers in Japan have now made a new paper-based material that could be an ideal replacement for those single-use plastics. The millimeter-thick paperboard reported in the journal Science Advances behaves like plastic, but only when needed. It is strong, transparent and shapeable, and it can hold boiling water, but it degrades within a year after settling on the ocean floor.

Plastic’s strength and durability is hard to beat. But those properties are exactly what make it an environmental nuisance: it lingers for hundreds of years in soils and waterways. And while biodegradable plastics or plastic alternatives exist, they often lack on performance. Soggy paper straws are an example.

Researchers from the Japan Agency for Marine-Earth Science and Technology struck a balance between performance and degradability with their new paperboard material. They start with cellulose, the molecule that makes up plant cell walls.

Mix. Remove Nanoplastics. Repeat.

Besides being used to make paper, cellulose is also used to make transparent cellophane sheets. But cellophane films can only be made less than 0.05 mm thick because the chemicals used to solidify the cellulose solution don’t work with thicker sheets.

The Japanese team found a workaround to that problem. They made a thick cellulose hydrogel by dissolving cellulose in an aqueous lithium bromide solution. Drying the hydrogel gave clear cellulose sheets that were a millimeter-thick. The researchers could shape the sheets to make cups or straws.

A cup made from the transparent material could hold just-boiled water for over 3 hours with no leakage. When the researchers coated the cup with a plant-derived fatty acid salt, it became completely waterproof.

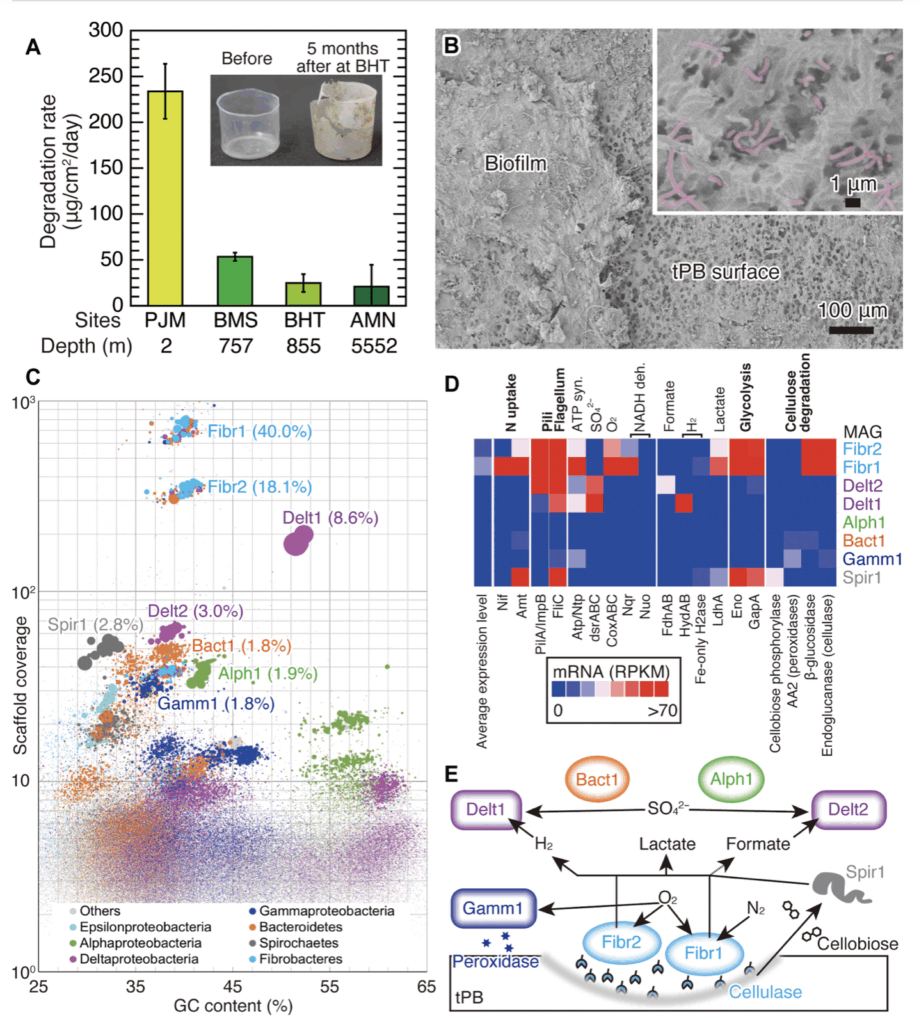

To test the degradability of the material in case of accidental release into the ocean, the researchers submerged paperboard sheets at sites located at four different ocean sites of varying depths. One was near a port at a depth of 2 meters, two were in waters around 750 and 850 meters deep, and the last one was submerged in deep ocean at a depth of over 5,550 meters.

Tests showed that the material fully decomposed in 300 days at deep ocean depths. The degradation was even faster in shallower depths because of warmer temperatures.

Source: Noriyuki Isobe et al. Fully circular shapable transparent paperboard with closed-loop recyclability and marine biodegradability across shallow to deep sea. Science Advances, 2025.

Abstract

To mitigate marine pollution from single-use plastics, it is crucial to transition to next-generation commodity materials that are derived from biomass and are recyclable and marine biodegradable even at abyssal depths in case of the accidental release to the ocean. Here, we develop an optically transparent millimeter-thick paperboard called transparent paperboard (tPB) through dissolution and coagulation of cellulose. The tPB is made entirely of pristine cellulose and compositionally identical to paper. A cup-shaped tPB can hold just-boiled water without an internal film coating because of its high wet tensile properties and anisotropic thermal properties. In addition, the spent tPB is material recyclable in a closed system, where all chemicals and water are also recyclable. Furthermore, the marine biodegradability of tPB across shallow to abyssal depths is confirmed by on-site degradation tests and metagenomic analyses. Hence, tPB is expected to serve as a key fully circular commodity material in sustainable societies of the future.

INTRODUCTION

Annually, 0.5 to 13 million metric tons of plastic waste are assumed to end up in the ocean (1–4). One fate of discharged plastic debris is that it remains on deep-sea floors (5, 6). A recent study (7) found that the plastic debris that drifts offshore is trapped in a gyre ~500 km away from land and ultimately sinks and accumulates on the deep-sea floor with a high density of more than 4500 items/km2; most of these materials are single-use plastics, such as food packaging or plastic bags. To mitigate this problem, the strict management of plastic debris is urgently needed (8, 9), in which all plastics should be collected after use and recycled to achieve a circular economy. However, a previous study has shown that strong winds and heavy rainfall induce the unavoidable accidental release of a large amount of plastic waste from land through rivers, making the complete recovery of plastic debris even more difficult (10). By considering these problems, a next-generation commodity plastic needs to meet the three following criteria (11): (i) to originate from biomass to reduce fossil fuel use, (ii) to be recyclable to achieve a circular economy, and (iii) to be marine biodegradable across shallow to abyssal depths in case of accidental release.

Paper is a long-standing versatile sheet material made from cellulose originating from plant cell walls. Paper thickness is an important parameter for its application. For printing and writing purposes, paper is generally thin, with thicknesses of 0.05 to 0.1 mm. Thick paper, with a grammage above 250 g/m2 or a thickness greater than ~0.3 mm, is referred to as paperboard (PB) (12); PB is used for packaging and containers because of its integrity and foldability. In response to increasing environmental concerns, PB has been focused on as a replacement for conventional petroleum-based plastics because of its biomass origin and recyclability (13). However, one of the drawbacks of PB is its opacity: Transparent packaging is impossible with conventional PB because of the light scattering induced by the macrofibers in wood pulps (14). Transparent packaging is aesthetically indispensable for commercial success in certain applications, such as food packaging or containers (15); thus, the use of petroleum-based transparent plastics, such as polyethylene terephthalate, is unavoidable, thereby necessitating the development of transparent PB, which is regarded as technically impossible (16).

Regenerated cellulose is another class of fully cellulose-based materials. Cellulose is solubilized into specific solvents (17–21) and solidified by immersion into nonsolvents, followed by thorough washing and drying. A transparent cellulose sheet with thicknesses of 0.02 to 0.04 mm, called cellophane, is produced on a commercial scale using this process. However, increasing the thickness of cellophane is limited because of the regeneration step: Solidification is driven by the diffusion of nonsolvents into the cellulose solution; thus, homogeneous and complete solidification is not possible at large thicknesses.

In this context, we develop a long-sought fully cellulose-based transparent PB-like material based on regenerated cellulose, denoted as transparent PB (tPB). This was achieved by the simple drying of thick, bulky, and shapable cellulose hydrogel prepared using aqueous lithium bromide (LiBr) solution as the solvent, where cellulose solution solidifies without the introduction of nonsolvents: Cellulose dissolves upon heating and solidifies upon cooling (22–24). With this process, tPB emerges as a transparent, three-dimensional thick material made solely from pristine cellulose, capable of taking various forms ranging from millimeter-thick board to cup or straw shapes. To date, transparent materials composed entirely of pristine cellulose have been limited to two-dimensional thin films with thicknesses below 0.1 mm (25–28). In contrast, while composites with resins can achieve thickness and transparency (29, 30), they are no longer purely cellulose based, thereby forfeiting the biodegradability and material recyclability inherent to purely cellulose-based material. There are four aims of this study: (i) to clarify the structure-property relationships, (ii) to demonstrate its three-dimensionally shapable nature, (iii) to examine the closed-loop recyclability, and (iv) to validate the marine biodegradability of tPB across shallow to abyssal depths and the corresponding mechanisms. Through these studies, we show that tPB meets the criteria for a next-generation commodity material: biobased, closed-loop recyclable, and marine biodegradable across shallow to abyssal depths.

DISCUSSION

The energy consumption during tPB production was compared to that of conventional PB (table S6). To produce plate-shaped tPB, 640 times more energy (4800 GJ/metric ton) was consumed compared to conventional PB (7.5 GJ/metric ton). This high energy input primarily originated from the press-drying (4710 GJ/metric ton), wherein only one postcard-sized sample could be prepared at a time using laboratory-scale electric apparatus. In contrast, cup-shaped tPB consumed only 8.5 GJ/metric ton during the drying step owing to the simple air-drying in an oven. The energetic efficiency indicates that the shaping of tPB does not increase and may even lead to a marked decrease in energy consumption during production. Contrastingly, shaping conventional PB requires additional energy input for processes such as punching, folding, and heat sealing. In general, energy consumption during production can be reduced through mass production. To reduce the energy input, modern paper mills use the heat of steam from boilers, which is significantly more energy efficient than heating with electricity (44). By using the cooker used in the kraft pulping process of commercial paper mills for the dissolution step in tPB production, the estimated energy consumption during dissolution is 2.7 GJ/metric ton. With this large-scale dissolution, the overall energy consumption for cup-shaped tPB production would decrease to 11.2 GJ/metric ton, which is only 1.5 times higher than that of commercial PB. This estimation suggests that mass-producing tPB with the same energy input as conventional PB would be feasible.

To evaluate the potential environmental benefits of tPB production, a life cycle assessment (LCA) was conducted. For this, we modeled an ideal mass-production process (fig. S15), where large-scale washing is carried out using a counterflow washing method, and wastewater is recovered and recycled using an energy-efficient technique developed to date. Under these ideal mass-production conditions, the greenhouse gas emissions by tPB production would be approximately three times that of conventional PB, three-quarters that of cellophane, and half to two-thirds that of plastic packaging (fig. S16). Therefore, replacing transparent packaging materials with tPB could be environmentally beneficial. In addition, a technoeconomic perspective was considered by factoring in the cost of dissolving pulp, which is approximately three times higher than that of conventional pulps used for PB. As a result, the estimated price of tPB is projected to be about three times that of commercial PB, demonstrating its economic feasibility. However, optimizing the production process—such as improving the energy-intensive drying stage and developing a continuous manufacturing process (fig. S15)—could further lower production costs, thereby enhancing its market competitiveness.

As suggested by the LCA calculations based on the ideal mass-production process, the repeated use of LiBr is a critical step for the large-scale production of tPB. To address this, the recycling of the solvent (60 wt % aq. LiBr solution) from wastewater (30 wt % aq. LiBr solution) was achieved through the condensation followed by the removal of by-products using activated carbon. Moreover, the water recovered during the condensation was reusable as washing water. Although LiBr solution was widely used to prepare cellulosic materials such as thin films (45, 46), scaffolds for tissue engineering (23, 47), foams (48), and aerogels (49–52), the recycling of the solvent used therein has not been reported to date. Although LiBr solution is stable and nontoxic, it has a corrosive nature. However, the safe manipulation of highly concentrated LiBr solutions on an industrial scale has already been established. This is exemplified by the utilization of metric ton-scale 60 wt % aq. LiBr solution as a working fluid in the absorption heat pump system of air-conditioning, chiller, and refrigerator in industrial plants and large buildings (53, 54). In the absorption heat system, the dilution (from 60 to 40 wt %) and condensation (from 40 to 60 wt %) of aqueous LiBr solution are continuously repeated (55, 56). Consequently, the condensation conducted in this study can be scaled up to a commercial level. In addition, energetically efficient processes without heating such as electrodialysis (57) and vacuum membrane distillation (58) were already demonstrated in LiBr condensation. Furthermore, a solar-powered cooling system (10-metric ton scale) based on LiBr solution has already been installed in Thailand (59). These indicate that tPB production can be transformed into a completely closed process in a cost-effective and environmentally benign manner.

The spent tPB was successfully transformed back into tPB, demonstrating closed-loop recyclability. In each material recycling, the weight-average molecular weight (Mw) decreased by ~18% (fig. S17A). This decrease in Mw was comparable to polyethylene terephthalate, one of the well-known recyclable plastics (60). Considering the lower limit of molecular weight required for tPB preparation, it was determined that the maximum amount of material recycling should be limited to three times (fig. S17B). To address this wear-out, the addition of virgin cellulose, commonly used in paper recycling, would prove beneficial.

The tPB exhibited marine biodegradability with a substantial decomposition rate observed from shallow to abyssal depths. It is known that biodegradation speed at the deep-sea floor is extremely slow compared to on land (61–64). Therefore, the confirmed deep-sea biodegradability in this study is indicative of fast biodegradation in the soils. In addition, the effect of fatty acid salt (aluminum distearate) coating of cup-shaped tPB, as shown in Fig. 3 (C and D), is considered negligible in terms of marine biodegradability. This is attributed to (i) the one-sided and <10-μm thickness of the coating layer, (ii) fatty acid being a natural product that can degrade in the sea (65), and (iii) the ubiquity of aluminum in the seawater [3.8 to 6.1 Tg/year of global input to the ocean (66, 67)].

Achieving these advantages—transparency, high mechanical properties, shapability, solvent and material recyclability, and marine biodegradability—is feasible only with tPB. Compressed delignified wood, another class of single-component cellulose material with extraordinary mechanical properties because of the preserved structure of wood cell walls (68, 69), exhibits thinness (less than 100 μm) and haziness (Tt was more than 60% at a thickness of 50 μm) and is not material recyclable. Through the utilization of unexploited cellulose wastes such as worn fabrics, waste papers, and low-value wood, tPB can play a pivotal role in the sustainable circular economy of the future.