Researchers say sealing old oil wells with bio-oil from crop waste is a dual carbon-removal solution

A new analysis shows that oil made from corn husks, wood chips, and other waste could plug greenhouse gas-belching abandoned oil wells while sequestering carbon for about $152 per ton

By Anthropocene Team September 11, 2025

There are hundreds of thousands of abandoned oil and natural gas wells in the U.S. These orphaned wells, most of them uncapped, create significant emissions and pose safety risks.

Plugging the wells with oil made from plant-based waste such as corn husks, wood chips, and switchgrass could be a cost-effective way to reduce well emissions and storing carbon. Researchers from Iowa State University presented a detailed analysis of this two-for-one solution in a paper published in the journal Energy Conversion and Management.

Bio-oil has recently garnered interest as a way to offset carbon emissions. Big tech companies such as Alphabet and Meta, for instance, have recently funded a San Francisco-based bio-oil startup called Charm Industrial. The startup collects agriculture and forestry residues and heats it up to 500 degrees Celsius in a reactor.

The process, called pyrolysis, is carried out in the absence of oxygen so the biomass does not burn, but instead turns into a thick, tarry liquid. The company injects this bio-oil into underground wells.

Just like biochar, a charcoal-like solid created using pyrolysis that is applied to soilas a fertilizer, bio-oil offers a way to sequester carbon. If the biomass were burned or decomposed in the open, that would release carbon dioxide into the atmosphere.

Fossil fuel’s leftover infrastructure may have a surprising new ecological role

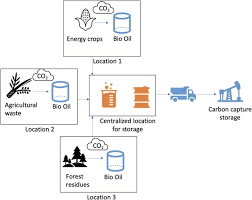

Charm supported the new study, in which researchers from Iowa assessed the technical and economic viability of a bio-oil sequestration system. The team evaluated the operation of a network of 200 mobile bio-oil production units across the U.S.

They estimate that each unit production unit would cost around $1.3 million to build. The system would sequester carbon for approximately $152 per ton. This is comparable with today’s carbon removal technologies such as direct air capture that require far more initial investment.

Further, their calculations showed that the machines could process 10 metric tons of biomass per day, producing 2.5 metric tons of biochar and 5.3 metric tons of bio-oil. The oil would have to sell for at least $175 per metric ton to be economically viable.

But injecting it into uncapped oil wells offers the best use for bio-oil. Filling an average-sized crude oil well using conventional routes takes more than 216,000 gallons of liquid, costing about $1 million. Plugging them instead with bio-oil would be a carbon capture route that also creates a market for agricultural waste.

Source: Pallavi Dubey et al, Enhancing carbon removal via scalable on-site pyrolysis and well-plugging systems, Energy Conversion and Management, 2025.